Professional CNC Precision Machining Solutions: Your Trusted Manufacturing Partner in China

We are a professional precision machining manufacturer with strong production capacity and international quality standards. Equipped with advanced processing equipment and a professional technical team, we adhere to strict quality control systems, ensuring high precision, stability and on-time delivery of every order, fully meeting the rigorous requirements of European and American markets.

✓ ISO 9001:2015 Certified

✓ Ships Global in 3-5 Days

Our Manufacturing Capabilities

To help you quickly understand our production strength, here is an overview of our core equipment:

VMC855

VMC1160

VMC1270

VMC1580

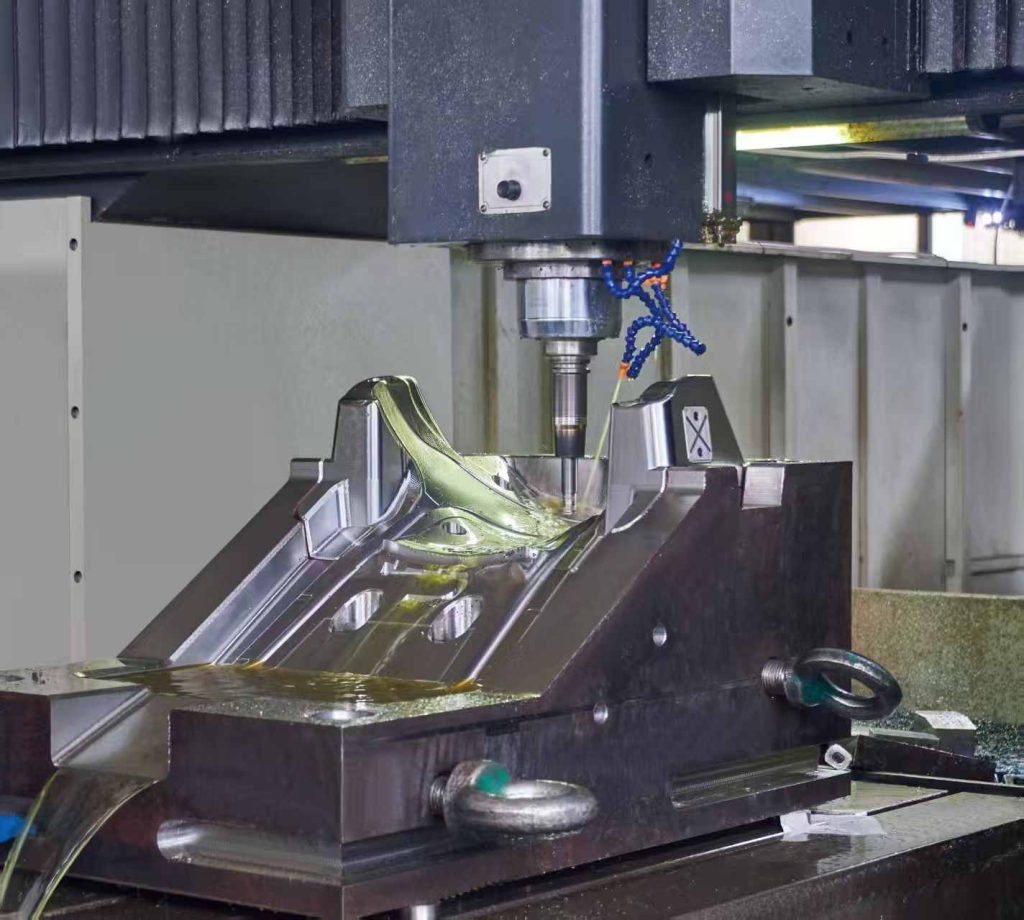

Vertical Machining Centers (Approx. 50 units)

Efficient, high-precision machining of plates, discs, and valve components.

HMC500

HMC630

HMC800

HMC1000

4-Axis Horizontal Machining Centers (4 units)

Suitable for multi-sided machining of enclosure components, completing multiple operations in a single setup

VMC1370-5X

VMC1160-5X

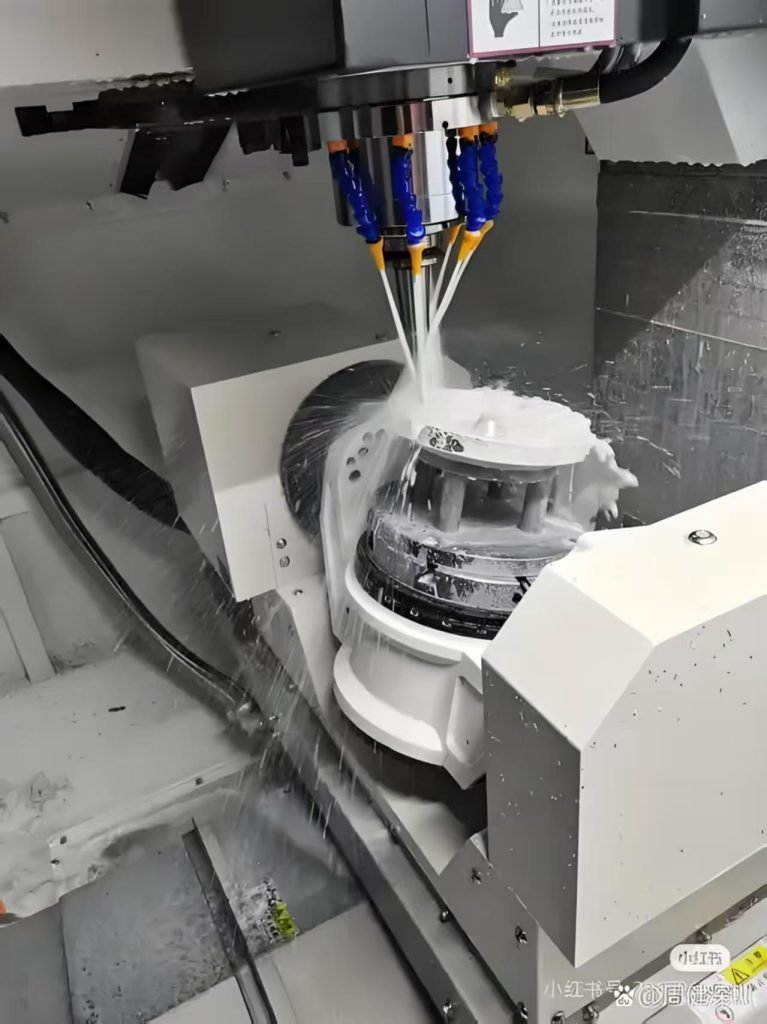

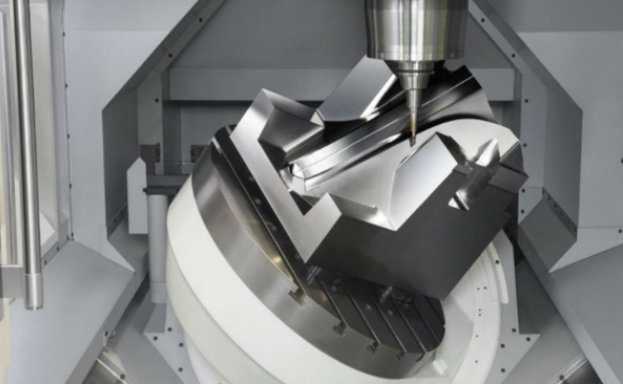

5-Axis Machining Centers (6 units)

Specialized in high-precision machining of complex 3D contour parts such as impellers, turbine blades, and precision molds.

GM3216

GM4028

GM6032

GM8042

5-Face Gantry Machining Centers (4 units)

Designed for high-precision, high-efficiency 5-face machining of large, heavy workpieces, featuring high rigidity and load capacity.

Professional Skilled Team

Over 50 experienced operators and programmers, ensuring production quality and efficiency.

Your Tailored Machining Solutions

We are a professional precision machining manufacturer with strong production capacity and international quality standards. Equipped with advanced processing equipment and a professional technical team, we adhere to strict quality control systems, ensuring high precision, stability on-time delivery of every order, fully meeting the rigorous requirements of European and American markets. We focus on solving core challenges for global clients, including custom precision component manufacturing, high-efficiency production optimization and cost-effective solutions. With rich experience in overseas cooperation, we provide one-0stop machining services tailored to diverse industry needs, delivering reliable quality, technical support and efficient communication to enhance clients’ product competitiveness and support their business growth.

Why Choose Us?

At Shandong Apex Precision Machinery, we offer more than just parts — we provide a reliable manufacturing partnership.

Proven Experience

With 15 years of serving demanding industries such as automotive, aerospace, and industrial machinery, we understand the challenges of complex projects and deliver solutions that meet high standards.

Dedicated Team

Our skilled workforce of approximately 100 employees, including engineers and quality control specialists, is fully committed to ensuring the success of your project.

Stringent Quality

We maintain certified integrated management systems (ISO 9001, etc.) to guarantee consistent and reliable quality for every order, regardless of size or complexity.

Reliable Delivery

Through efficient project management and full in-house control over the manufacturing process, we ensure your deadlines are met and your projects run smoothly.

Professional QC Team and Comprehensive Inspection Solutions

Behind every stage of production in our factory stands a dedicated QC team of 8 elite professionals. With profound expertise and meticulous dedication, they establish a full-process quality safeguard spanning raw materials, manufacturing, and final delivery. We firmly believe that precise data is the only language of quality. Therefore, we are equipped with advanced inspection systems covering dimensions, materials, performance, and appearance, ensuring every product meets your expectations.

30+ Engineering-Grade Materials

From prototyping plastics to aerospace-grade titanium. We stock a wide range of materials and provide full material certifications (RoHS, MSDS, CoC) upon request.

Aluminum (6061, 7075)

Lightweight, high strength-to-weight ratio. Ideal for aerospace and housings.

Stainless Steel (303, 304, 316L)

Corrosion-resistant and durable. Perfect for medical and food-grade applications.

Brass (C360)

Excellent machinability and electrical conductivity. Used in fittings and contacts.

Titanium (Ti-6Al-4V)

Superior strength and biocompatibility.

Copper (101, 110)

Highest thermal and electrical conductivity.

ABS

Versatile and impact-resistant. Great for general-purpose prototyping.

POM (Delrin/Acetal)

High stiffness and low friction. Ideal for gears and moving parts.

Nylon (PA6, PA66)

Tough and wear-resistant. Suitable for mechanical components.

Polycarbonate (PC)

Transparent and high impact strength. Used for lenses and guards.

PEEK

High-performance thermoplastic for extreme thermal and chemical environments.

Material Traceability

All materials are sourced from certified suppliers. Heat numbers and material test reports (MTR) are available for every order.

Our Service Process: Clear & Reliable

Requirement Communication

Understand product functions, performance targets, budget, and schedule.

Solution Design

Provide preliminary design solutions, 3D models, or technical recommendations for confirmation.

Engineering Drawings

Complete all part drawings, assembly diagrams, and technical specifications.

Production & Manufacturing

Mobilize factory resources (CNC lathes, milling, grinding, welding, etc.) for precision machining.

Quality Control

Use CMMs, hardness testers, and other equipment to inspect finished products strictly.

Delivery & Support

Deliver qualified products on time and provide necessary technical support.

Industries Served

We provide custom components for:

Automotive

Industrial Machinery

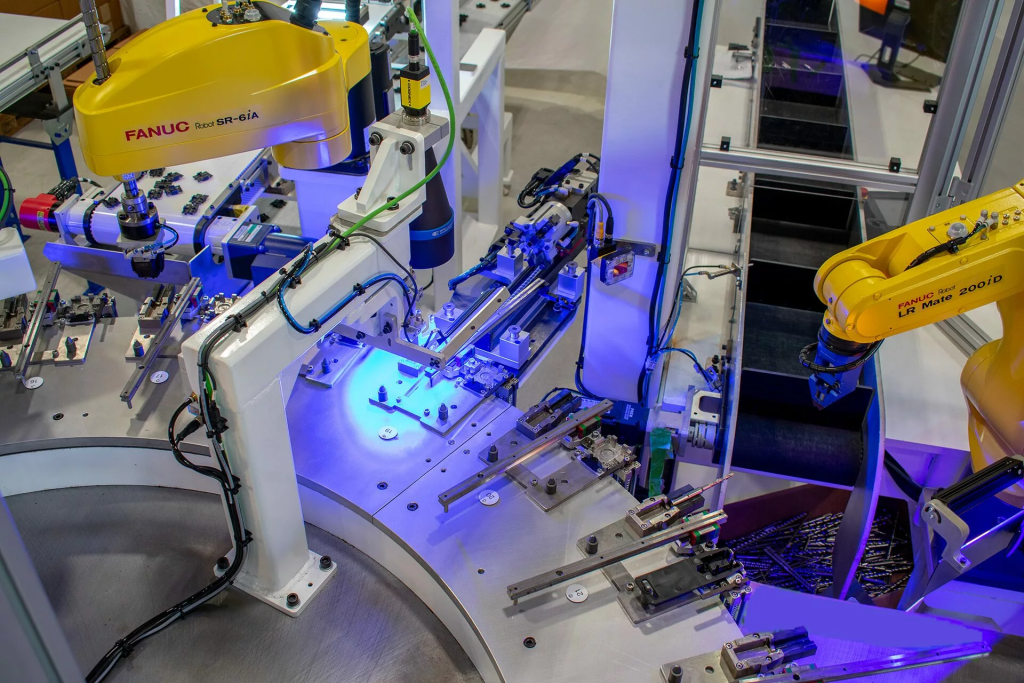

Automation Equipment

Medical Devices

Aerospace & Aviation

Engineering Machinery

Industries Served

Consultation & DFM Analysis

Share your requirements. Our engineers provide expert Design for Manufacturability (DFM) feedback to optimize your design.

Precision Manufacturing

We utilize our full capabilities to manufacture your parts to exact specifications.

Rigorous Quality Assurance

Every part undergoes strict inspection before shipment.

On-Time Delivery

We ensure your custom solutions reach you reliably.

Ready to experience a manufacturing partnership that delivers tailored solutions?

Contact us today to discuss your specific needs and request a competitive quotation. Let Apex Precision be your strategic partner in China.

Trusted by Innovators

What Our Customers Say

Thank you for the parts processed by your factory for us, with excellent quality and precision in place, which fully meets our requirements. At the same time, the team service is professional and meticulous, the response is timely, and the cooperation experience is very good. We look forward to more opportunities to work together in the future to create a win-win situation!

Jon

Mechanical Engineer

The CNC machined parts delivered by your factory have been inspected and their quality indicators fully meet our technical requirements. During the cooperation, your factory's service response and communication efficiency have also been excellent. We would like to express our gratitude and hope to maintain a long-term and stable cooperative relationship in the future.

Ethan

Purchasing Manager

After our company put forward the urgent delivery demand of C N C processed parts, your factory responded efficiently and completed the delivery on schedule, and the parts were fully tested, the quality indicators met the technical standards, and the professional ability and service efficiency were worthy of recognition, and we look forward to continuous cooperation.

Rodney

Engineering Manager

Been their industrial equipment customer for five years. From the initial sporadic proofing, all core components are produced by it. Consistent accuracy and reliability allow us to fully focus on the development of the complete machine without worrying about the supply chain.

Lucas

Engineering Manager

It's our first time to cooperate with your company, and we have truly felt your pursuit of ultimate quality. The parts we received were not only individually packaged, but also had comprehensive anti-collision treatments on the edges and corners. Moreover, the attached test data exceeded our requirements by three items. Your attention to these details has made us highly recognize your company, and we sincerely thank you for safeguarding us with such a professional attitude. We look forward to continuing our cooperation in the future!

James

Executive Director

When our new project encountered technical challenges, many suppliers chose to give up. But you demonstrated a true spirit of partnership – your team of engineers didn't shy away from the problem, but took the initiative to analyze it with our team late into the night. Their proposed improvement plan demonstrated exceptional professionalism and ultimately solved the problem that had plagued us for months. This convinced us that choosing you is choosing the most reliable partner.

Alex

Mechanical Engineer

Ready to Build?

Our engineers are standing by to review your project. Upload your drawings now for a secure, confidential quote.

contact@apexmachinary.com

Phone

+86 555 66545